q-doc® – Data Management Software

Single workstations and networked solutions with built-in data integrity.

- 100% scalable 3-layer software architecture with central MS-SQL database

- Powerful framework with device-independent methods that can be used for different instrument types

- Modules extend the basic functionalities with LDAP integration, LIMS export, data trending, and more

- More than 35 drivers for dissolution and physical testing instruments

- Report, check & evaluate data directly in q-doc and sign with electronic signatures

- Easily create complete batch reports and compare batches over time intervals

- Human readable audit trail and product version control for full traceability and compliance

- Fulfills all requirements for implementation of a 21 CFR part 11 compliant system

Highlights

Integrate Instruments.

Standard q-doc® drivers integrate more than 40 instrument types from different brands – controlling test parameters and automatically recording results. Boost lab efficiency and safeguard critical test data with 100 % traceability according to 21 CFR part 11.

Integrate Processes.

Process drivers ensure that proper procedure is followed. Operators are guided through manual testing processes with step-by-step instructions. All user actions and meta data (e.g. date, time, serial numbers) are automatically protocolled and reported.

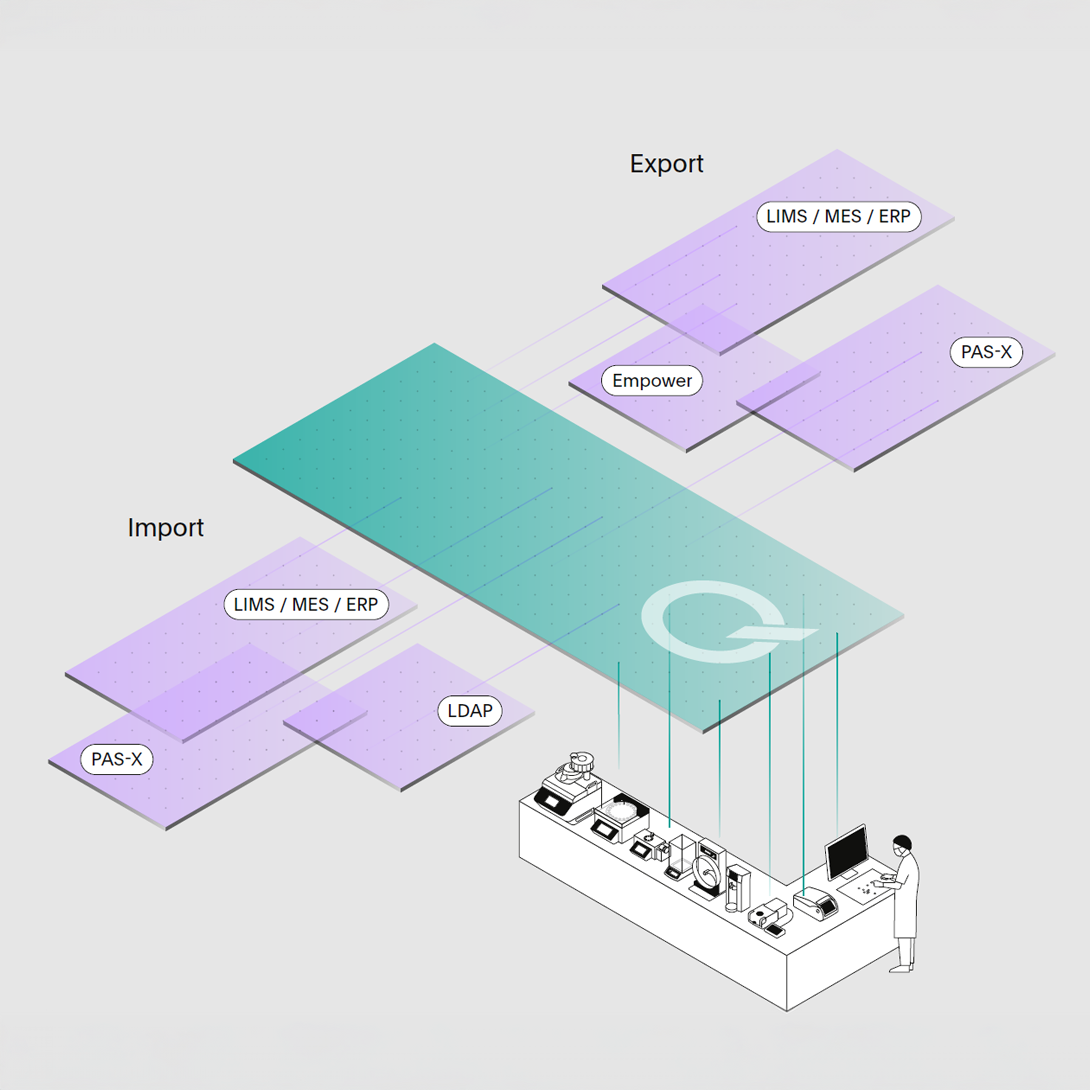

Integrate with your Ecosystem.

Run q-doc® seamlessly integrated with other data management systems for operational efficiency with enhanced traceability across digital platforms. Standardized DataLink™ interfaces allow to easily exchange data with your company's LIMS / MES / ERP including Körber PAS-X and Waters Empower® CDS.

Empower your AI with q-doc®

q-doc® simplifies and digitalizes documentation workflows – accelerating processes, reducing manual effort, and enhancing data integrity. Unlock faster, smarter operations and optimize Design of Experiment (DOE) parameters or enable predictive manufacturing. q-doc® delivers structured data ready for your company's Artificial Intelligence (AI) model – turning data into actionable intelligence.

Built-in Data Integrity.

q-doc® automatically tracks who did what, when, and where in an electronic audit trail that can easily be reviewed from any PC within the network. The product record includes all test methods, tolerance limits, criteria for pass/fail decisions, and specific device settings for all instruments where the product can be tested.

Operational Excellence in Dissolution.

Maximize instrument usage and send test runs to any dissolution tester in your lab. Analyze UV-Vis spectra online – or automatically create sample sets in Empower® CDS to link HPLC results to your dissolution data. Once a test has been completed, operators, supervisors, and managers can access detailed test reports from any PC in the network.

In-Process Control

Streamline in-process control (IPC) for rapid decisions – from raw material testing to powder characterization and testing the physical properties of final dosage forms.

q-doc® integrates manual inspections, connects instruments from different brands, and interfaces seamlessly with your MES for fully digital workflows.

Managing large Networks.

q-doc® connects departments to unlock significant cost savings – while simplifying complexity for operators and IT teams. Workgroups, virtualization, mobile access, and instrument pooling deliver clarity, boost flexibility, and strengthen security. Use a mobile tablet PC to easily assign instruments to yourself and return them to the shared pool when finished – ideal for R&D, education, or any environment where teams need flexible access to specialized testing equipment.

Future-Proof your Installation.

q-doc® software support contracts are all about future-proofing your installation. They combine fast and uncomplicated priority service with free update licences to be ready for tomorrow's challenges without unexpected costs.